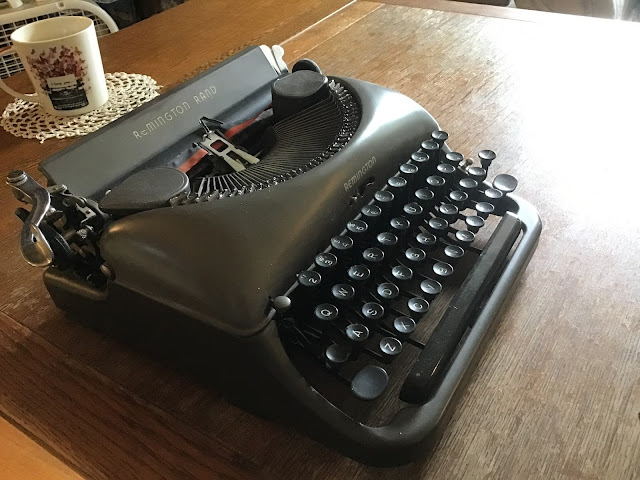

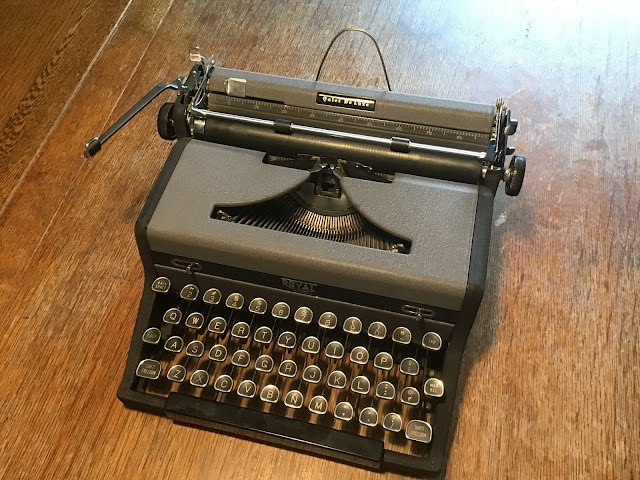

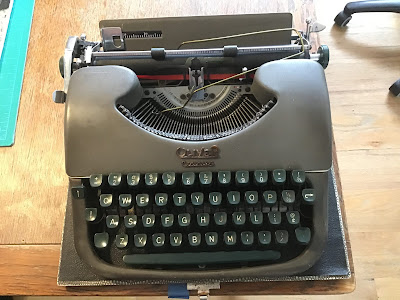

This typewriter has it all - sophisticated shape, tried and tested mechanism, and it's fun to type with it. The only thing missing is a paper support.

Building Custom Desks

David Randall's free blog on building

your own desk, other woodworking stuff, and fun with typewriters

Subscribe to Building Custom Desks in a reader, or fill in your email address below to follow by email.

Friday 2 July 2021

Typewriter paper support for a 1948 Remington Rand De Luxe Model 5

Tuesday 11 May 2021

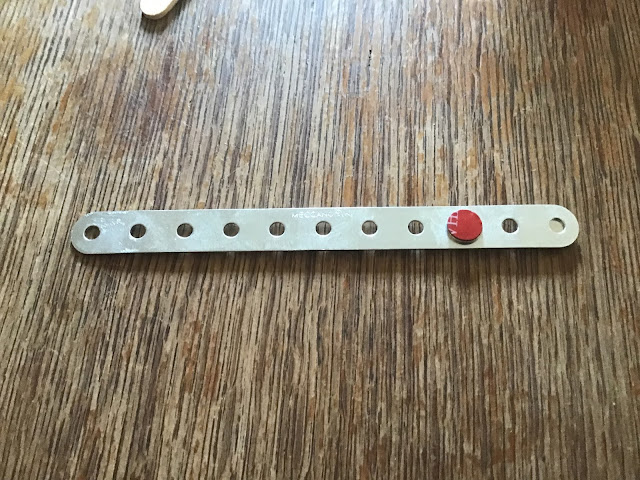

Typewriter paper support for a Remington Rand Model 1, 1937

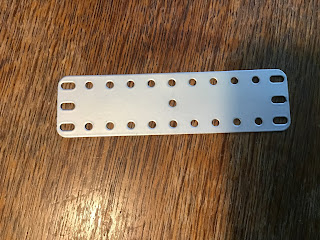

In one way, this is the simplest typewriter paper support, for a typewriter that doesn't have one. It is a Meccano or Erector Set flat strip, 11 holes by 3. It slides between the rear paper table on the carriage, the one you need to fold back to change the tabs, and the rubber tubing that holds the tabs in place, and stops them falling off the tab rack when the typewriter is in its case. A similar piece of plastic, 5 1/2" by 1 1/2" and about the thickness of a credit card would do the same job.

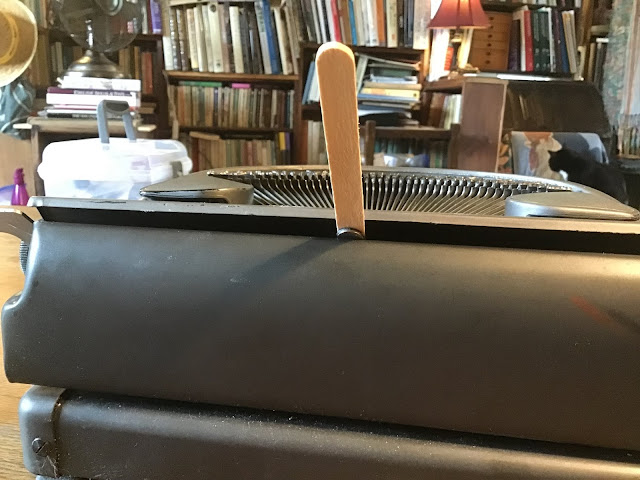

The rubber tubing that holds the tabs in place may be old, cracked and crumbly, like the example here:

If that is the case, you will need to replace it. Get a length of rubber tubing. I bought a couple of feet through Amazon.

This size is also handy for recovering some rollers. To remove the rod with the old rubber on it, you need to remove two screws. The top one holds the rod in place at the right hand end of the carriage. The bottom one holds the rod that the left hand paper guide slides on. As you do this the spring that works the folding back top will disconnect, but you can refit this with a spring hook, or a piece of bent wire as part of the reassembly.

Withthe new tubing fitted, it is easy to change the tabs by folding back the top of the paper table. When folded down again, the tubing holds those tabs in place. And, of course, you can fit your paper support!

Thursday 6 May 2021

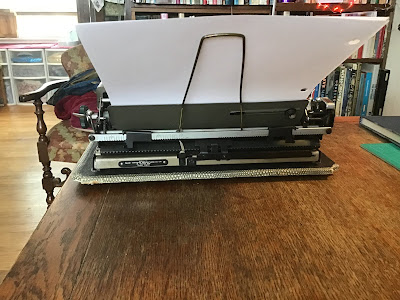

Typewriter paper support for a 1949 Royal Quiet De Luxe (Dreyfus Design)

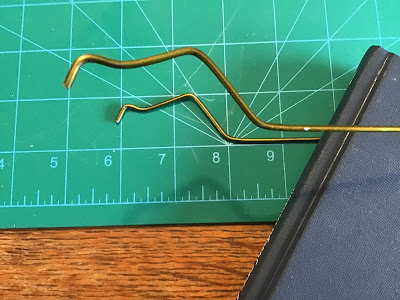

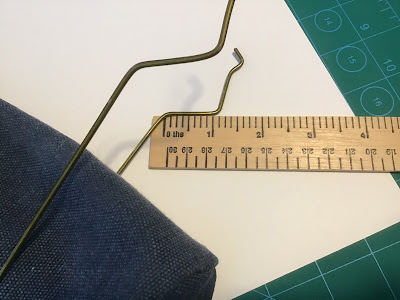

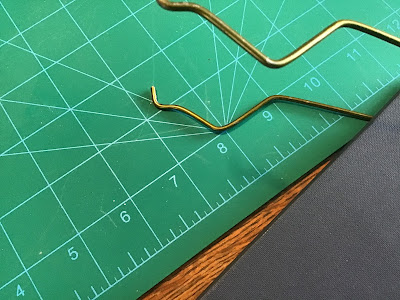

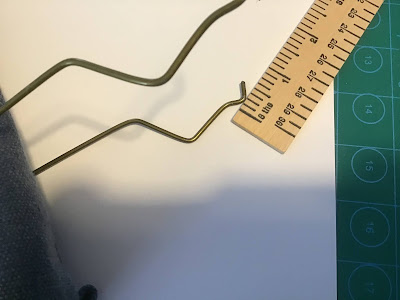

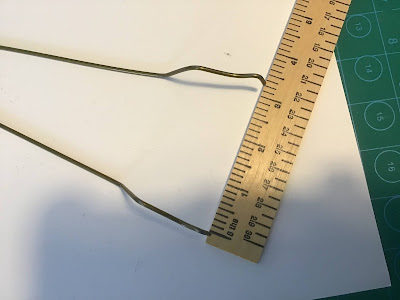

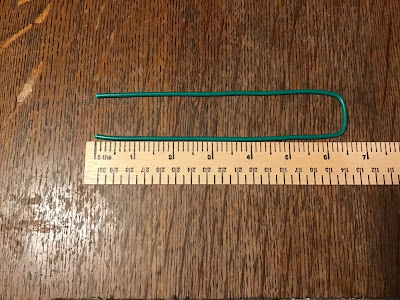

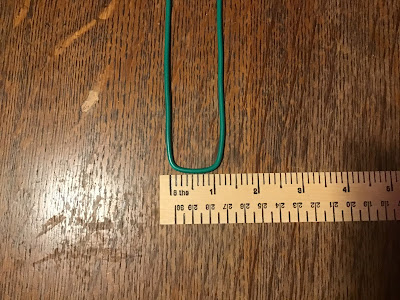

The Henry Dreyfus designed Royal Quiet De Luxe is a very nice typewriter to use, but it has no paper support. With a piece of coathanger wire and two magnets, you can make one! The magnets are the kind with 3/4” wide bases, and hooks screwed into them. I bought mine from Lee Valley Tools of Ottawa.

Unscrew the hooks so you just have the magnetic bases. Let the two magnetic bases adhere to the back of the carriage, centering them under each end of the Quiet De Luxe badge, and making sure you can swing open the cover that hides the margin settings.

Take a piece of coathanger wire, about ten inches long, and straighten it with pliers. You can substitute a similar guage of wire, as long as it is ferrous (can be attracted by a magnet). Make a loop with pliers at each end to go over the outside of the magnets. Bend the middle into a smooth curve, until the two looped ends will go over the magnets. Add a gentle backwards curve of maybe twenty degrees to align the support with the top of the carriage back.

Monday 8 March 2021

Typewriter - Adler J5, 1974, Replacement Feet

This Adler J5 is a lovely typewriter to use. Everything about this machine was in good as new condition, including the cardboard typebar protector. The only problem was the feet.

The replacement is in the same picture as the old foot. The new ones came through eBay from Alltrade Supply of California. The description for them is in the screenshot below. These come in a pack of 8.

Happy typing!

Saturday 13 February 2021

Typewriter paper support for an Oliver Courier, 1957

This British made Patria variant Oliver Courier typewriter is very portable, however it does not have a paper support. This is annoying if what you have typed so far is not visible. There is a paper table at the back, and with this design I used an old wire coathanger, and a single small electrical zip tie.

Sunday 7 February 2021

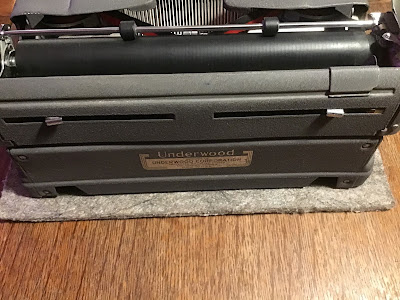

Typewriter paper support for an Underwood Champion 1950